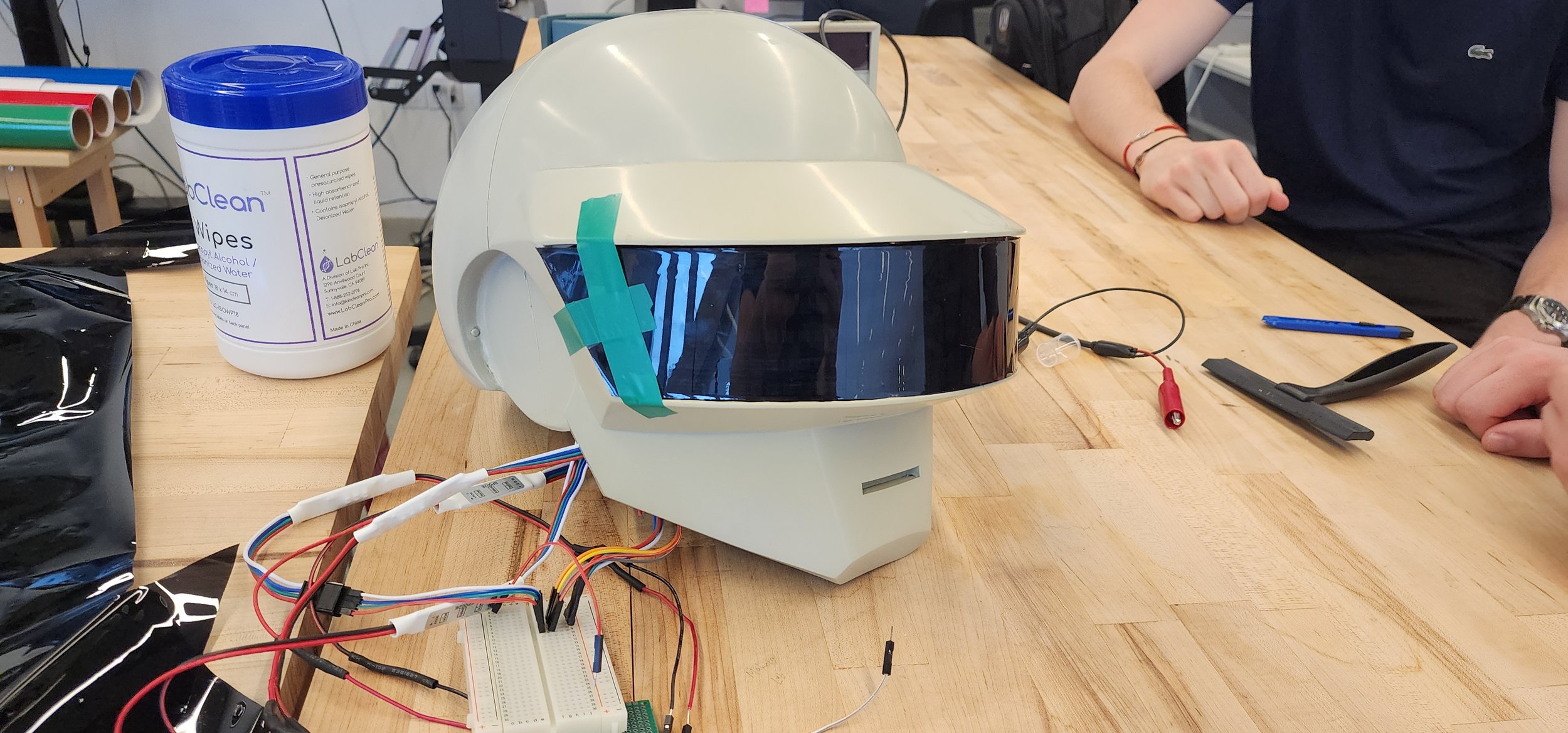

Daft Punk Custom Flexible PCB, Assembly, Rapid Prototyping and Fabrication

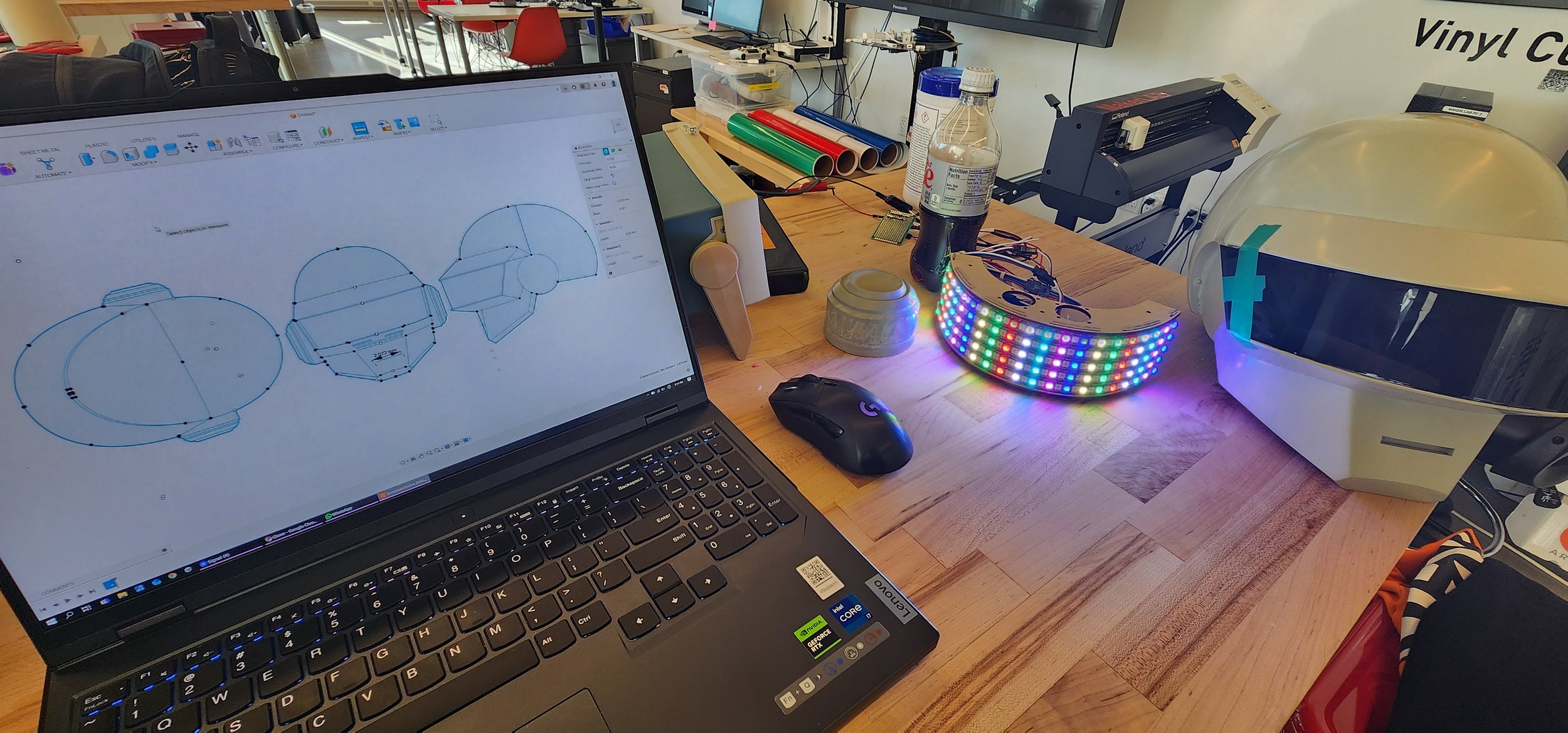

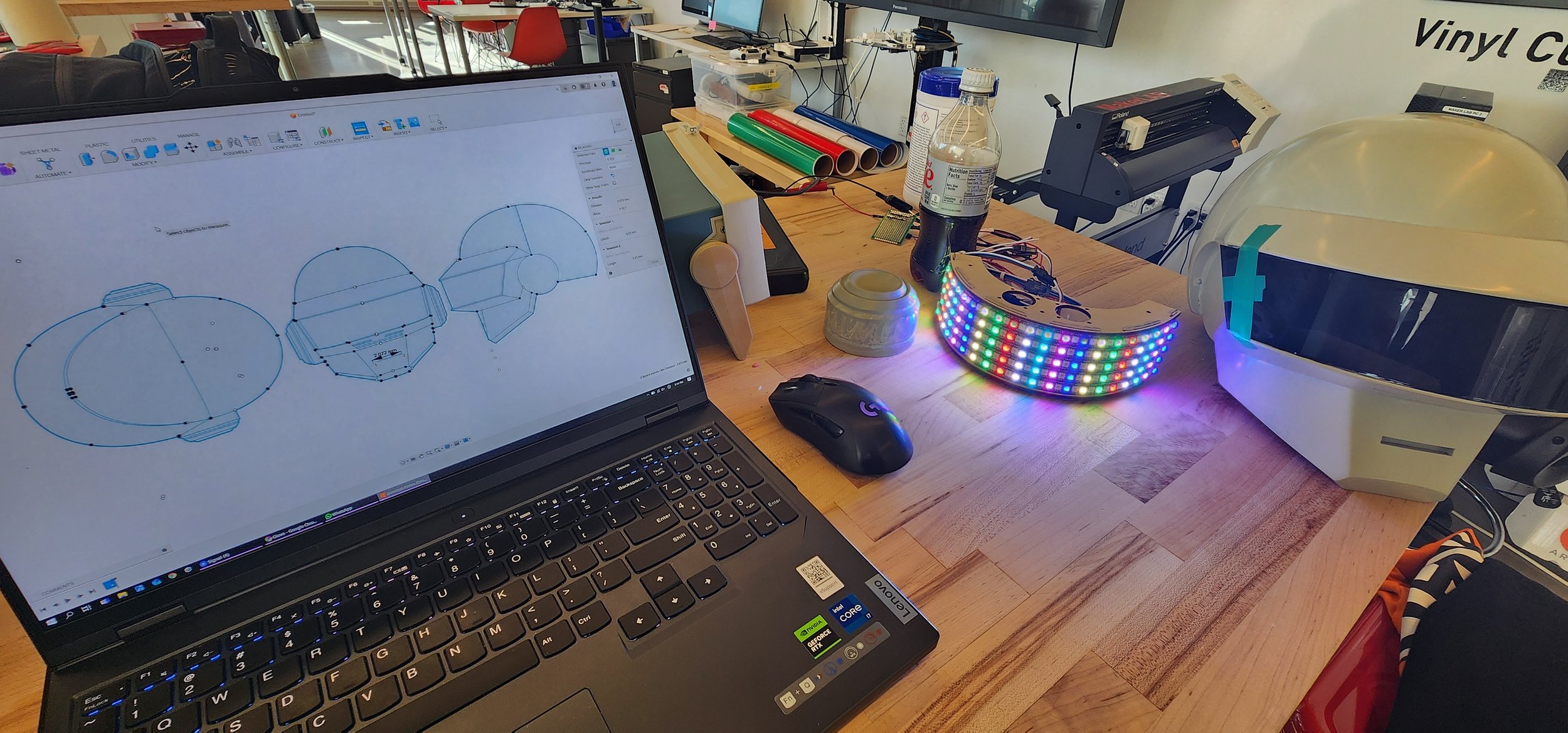

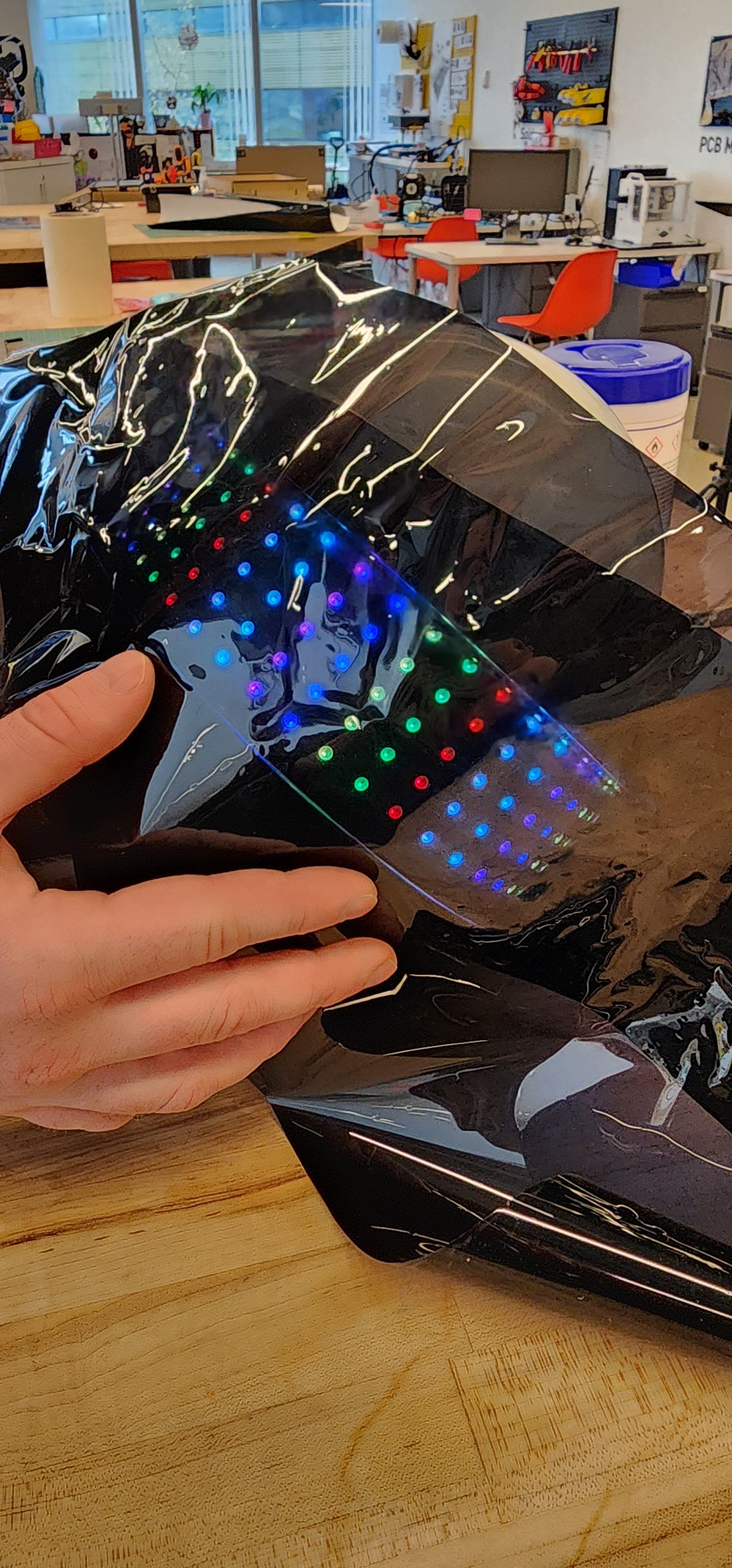

Flexible PCB Design

I designed a flexible PCB which was a modernized version of Thomas Bangalter’s iconic Daft Punk Helmet. These were originally made in the late 1990’s and updated over the course of Daft Punk’s career, so I wanted to keep it as true to the original as possible while also using addressable LEDs. The PCB was designed using Fusion 360 Electronics (and later re-built using Altium Designer) and incorporated the WS2812B-V5 addressable surface mount LEDs for their built in capacitors and low current draw. In total there were over 300 LEDs used in this design with a maximum power draw of 9 amps.

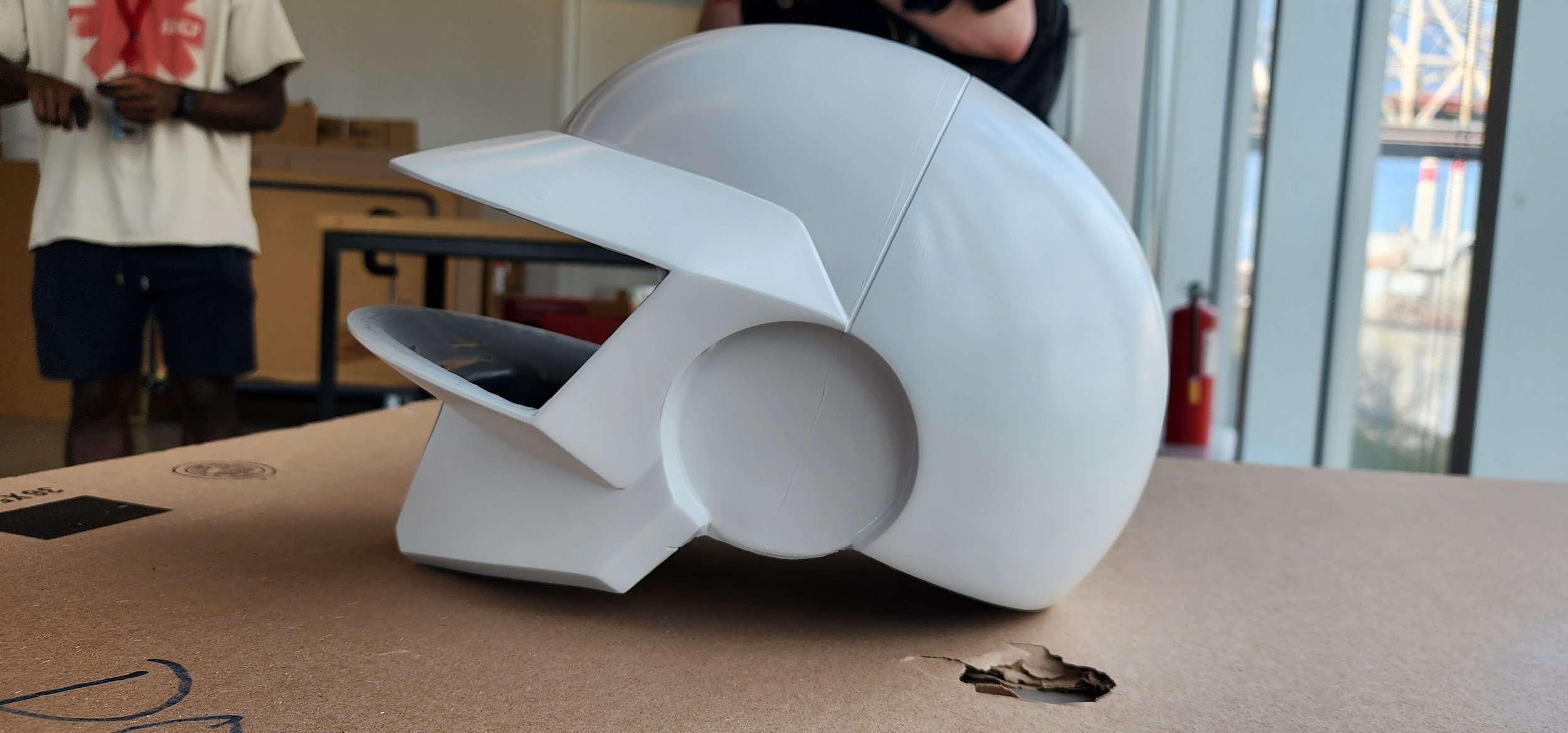

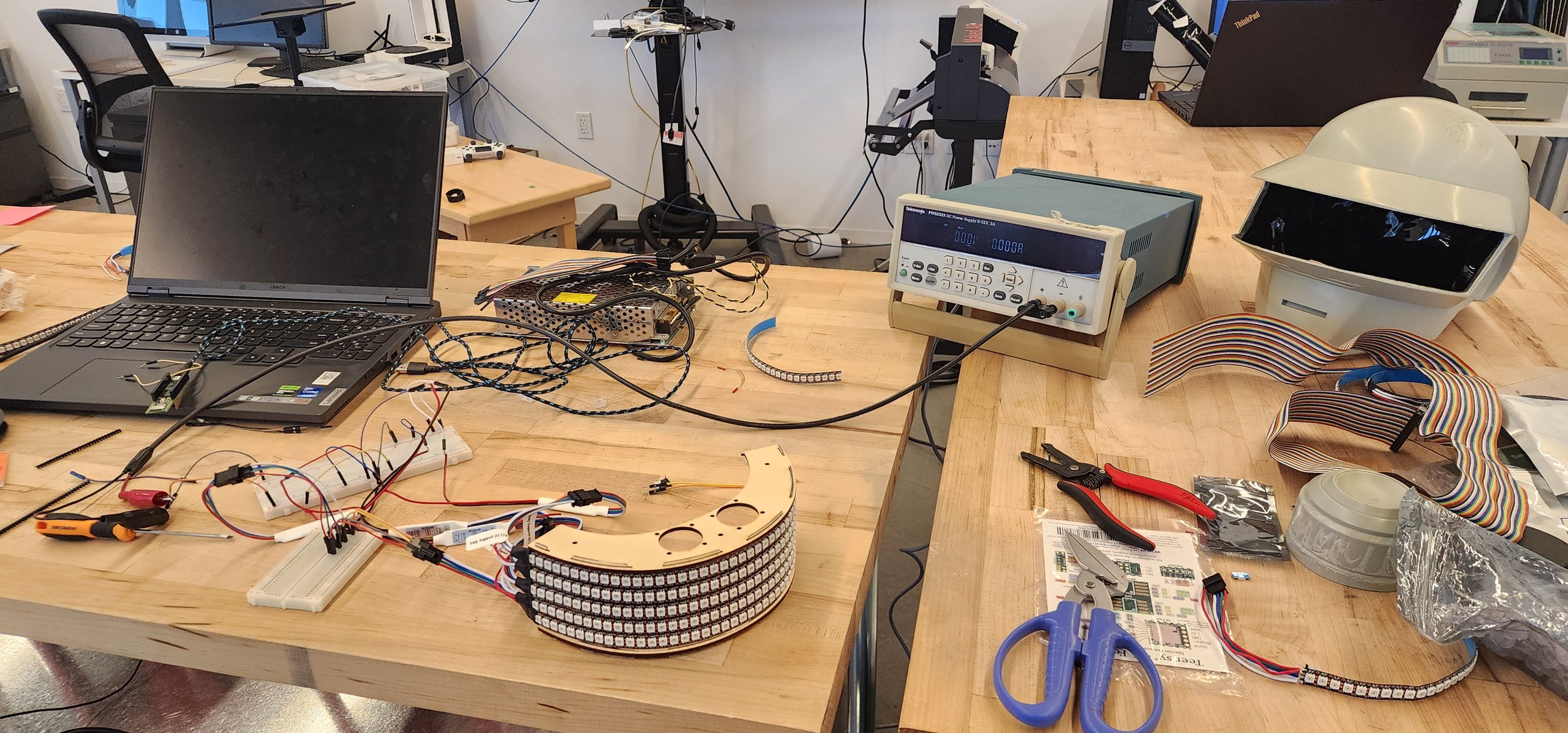

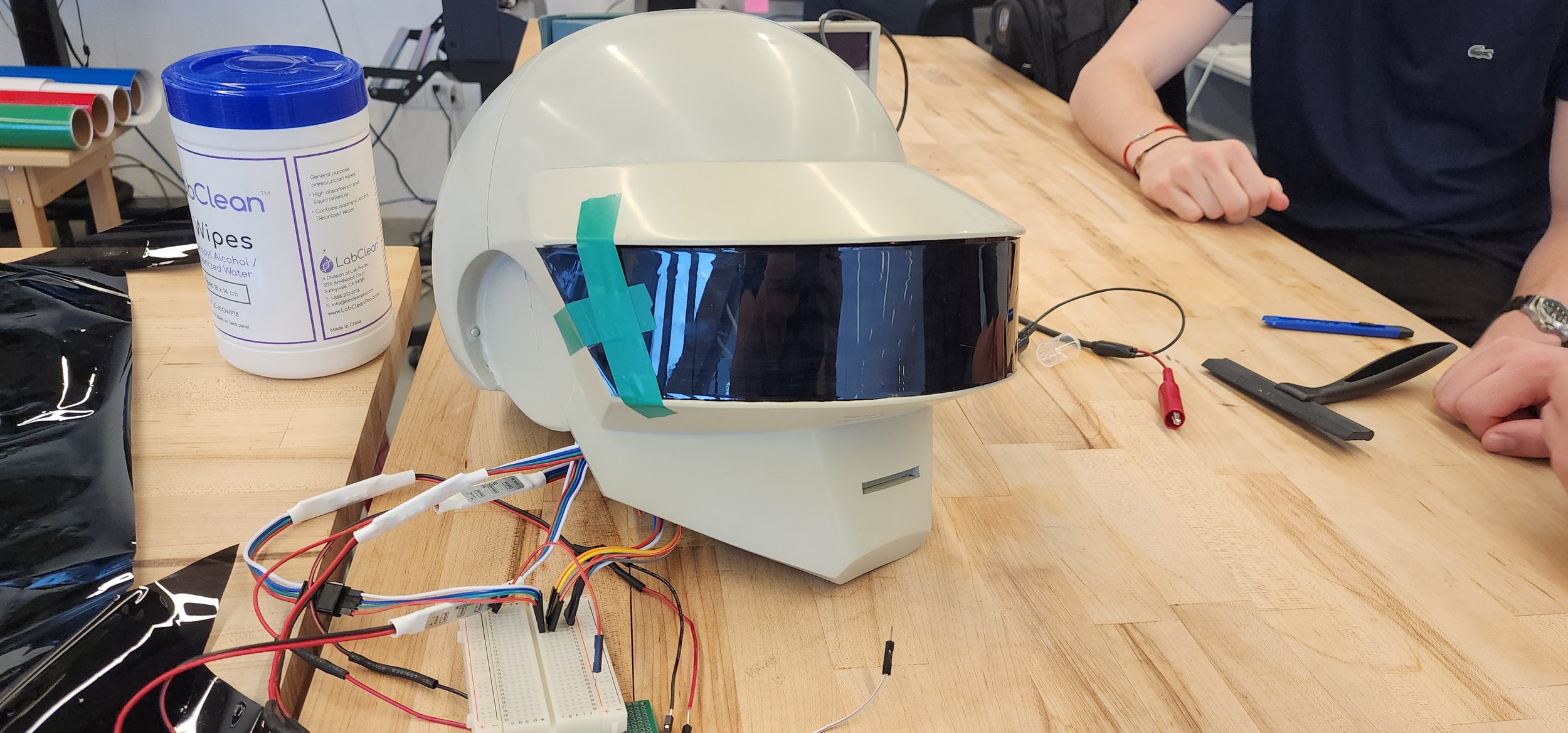

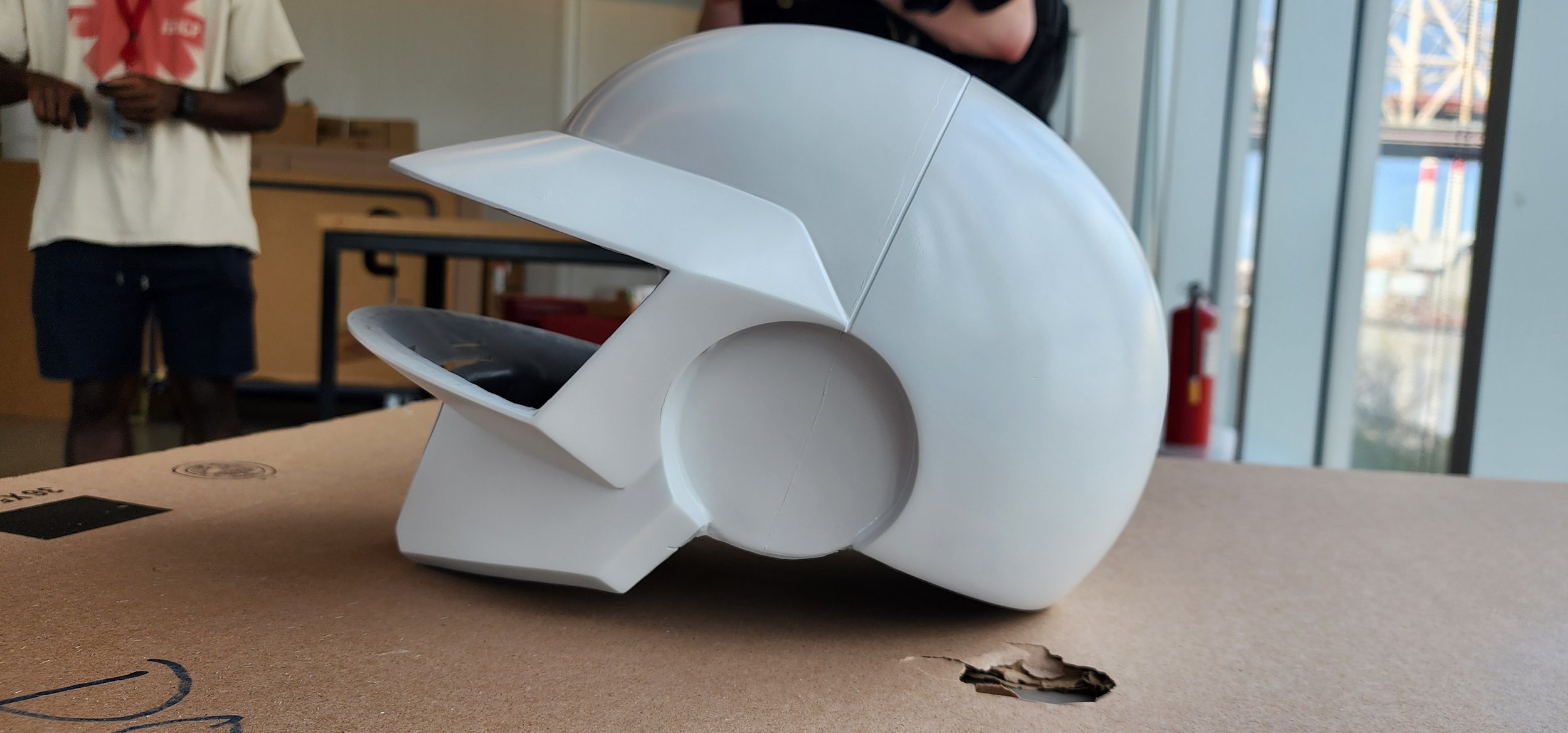

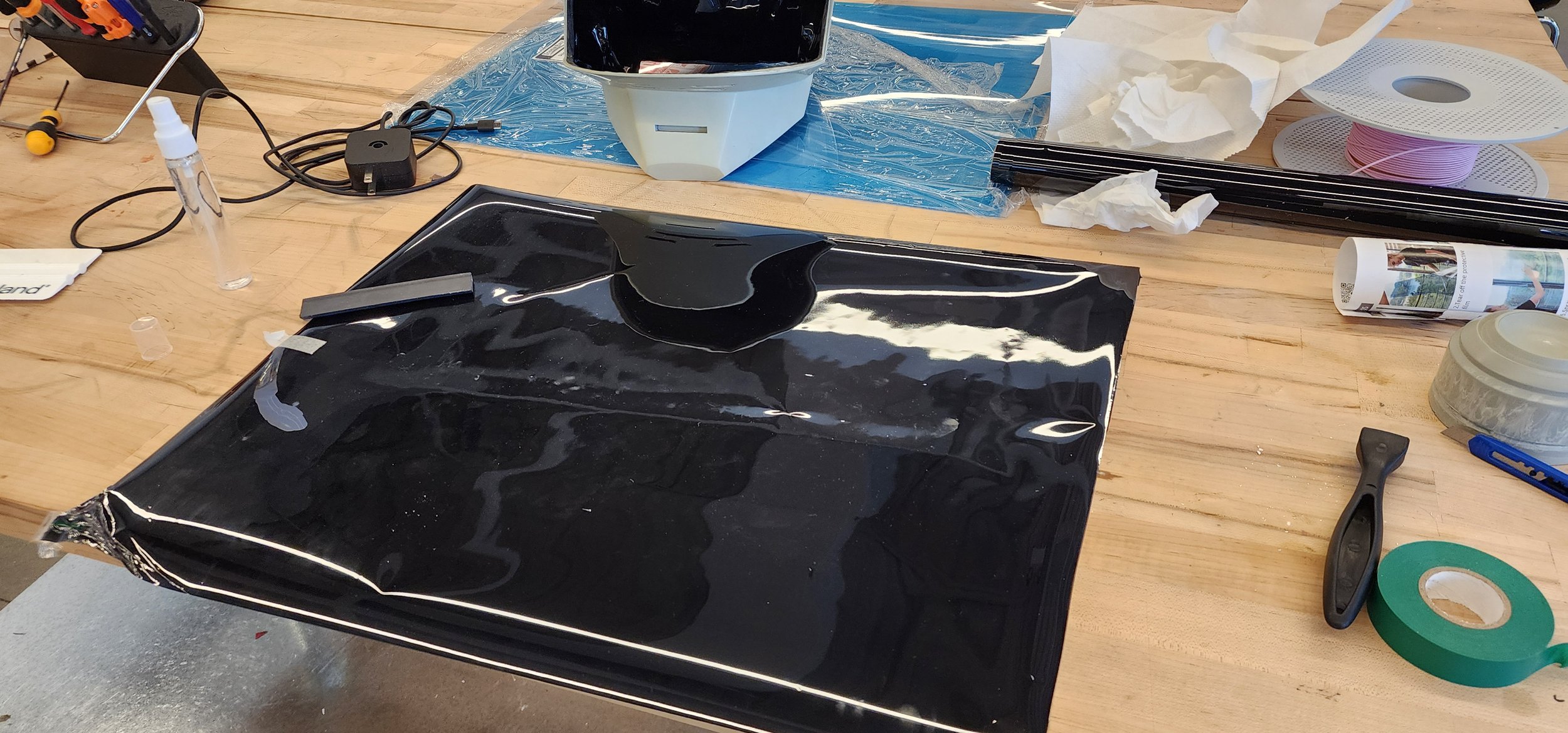

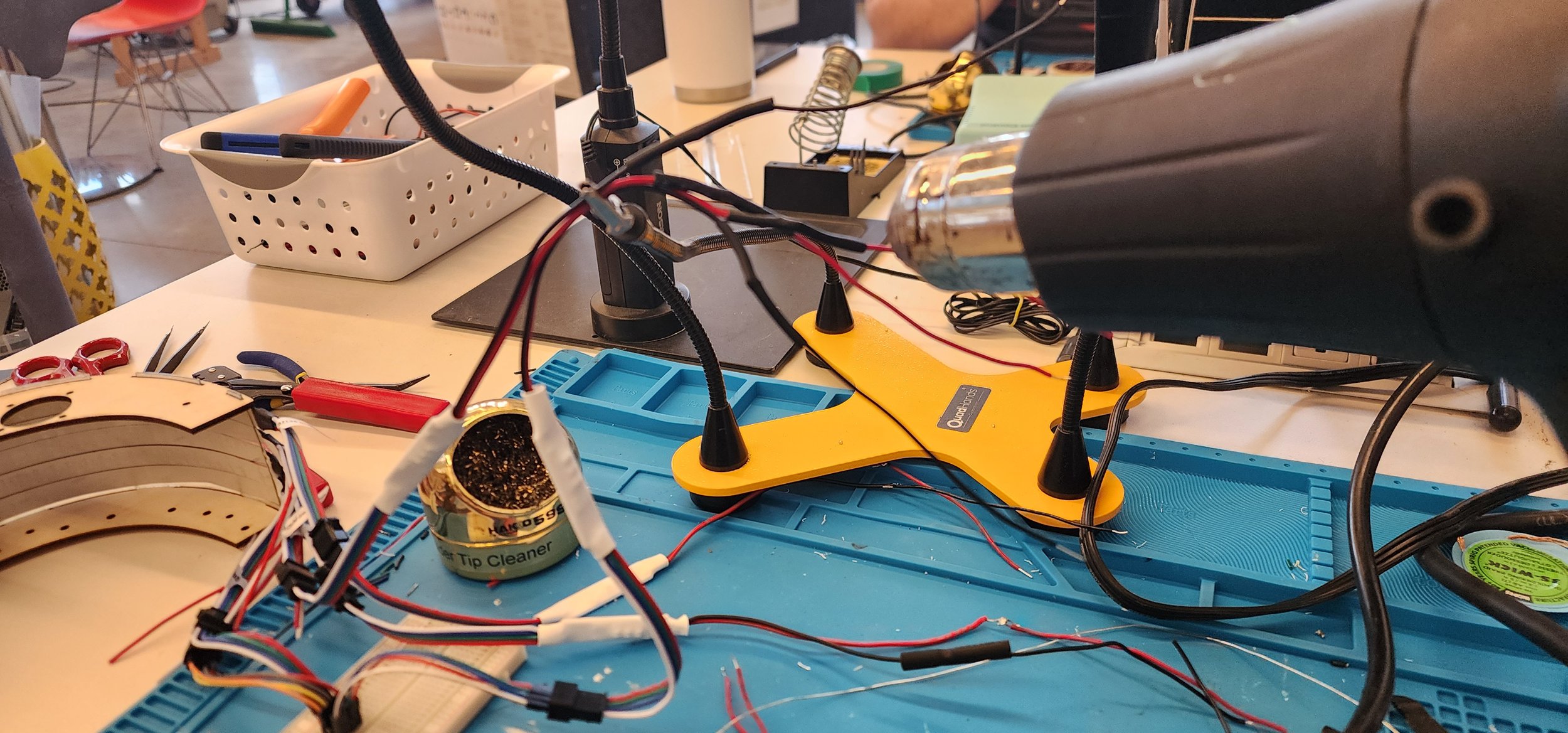

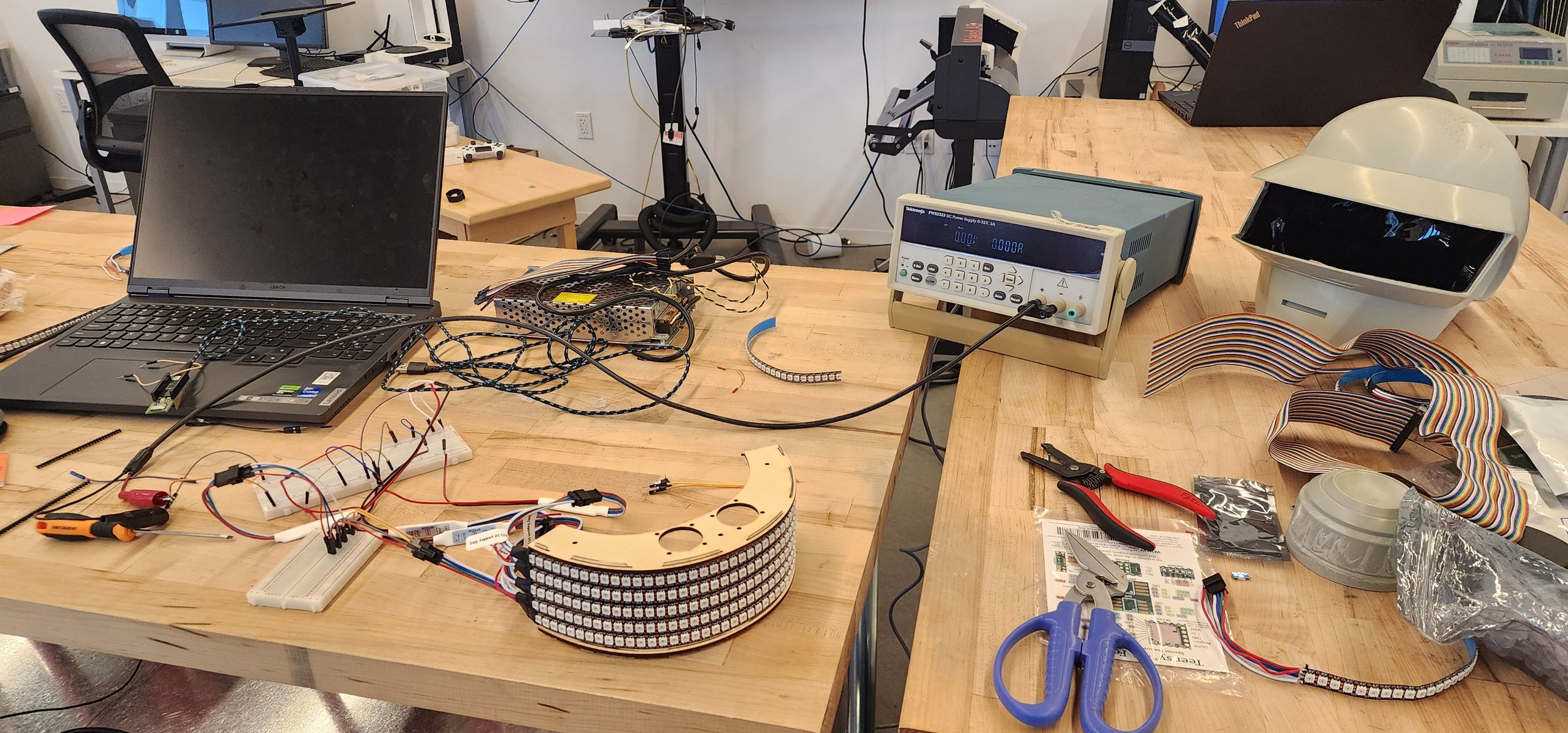

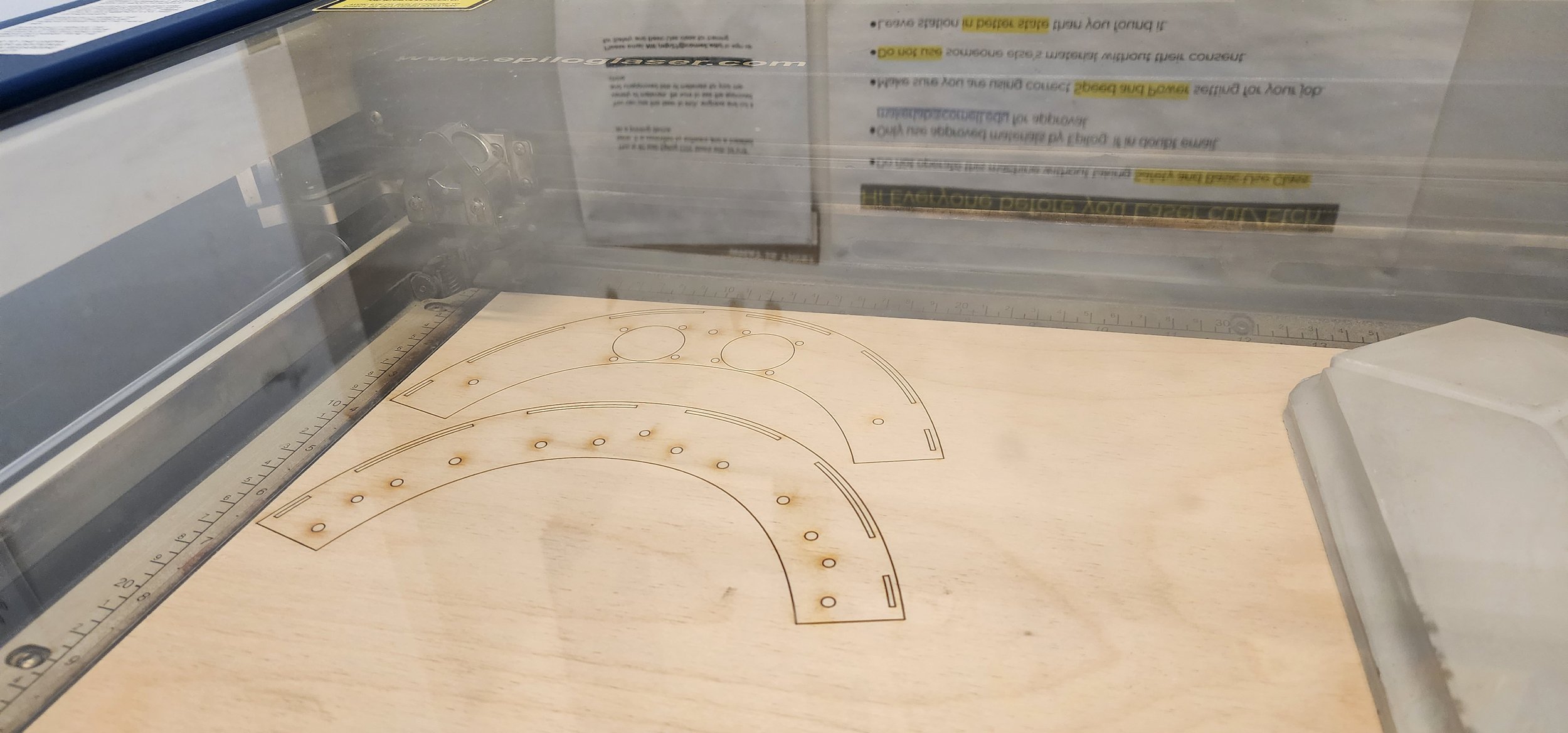

Helmet and Internal Component Fabrication

Fabrication of the helmet was done with the goal of production at volume. Initial rapid prototyping of the helmet was completed using 3D printed parts for external components and laser cutting for internal PCB mounting.

LED Programming

Initial LED programming was done with off the shelf prototype LED strips to test power consumption during various animations. Various microcontrollers were tested, but I eventually landed on an ESP32-WROOM microcontroller for remote bluetooth/WIFI control.